WHY USE NO LIMIT™ SCAFFOLDING SYSTEM?

The MonZon NO LIMIT™ SCAFFOLDING SYSTEM is developed as a result of many years of research and studies by our engineering department.

We have worked together with scaffolders and users from all over the world, from the construction industry to the oil and gas sector, to find problem areas that need to be solved and their requirements for a scaffolding system ready for the future.

The requirements were clear; scaffolders and users want ONE SYSTEM that can be built FASTER, one system that is as FLEXIBLE as tubes and couplers but also as EASY to erect as frame scaffolds.

The system must be LIGHT and STRONG to improve ERGONOMIC and ENVIRONMENTAL aspects with NO compromises on SAFETY.

We are very proud to present NO LIMIT™ – the new concept in the scaffolding industry! Take a look at how we did it.

NO LIMIT™ Video Presentation

Certified (not yet in Germany) or conforms according to the following standards:

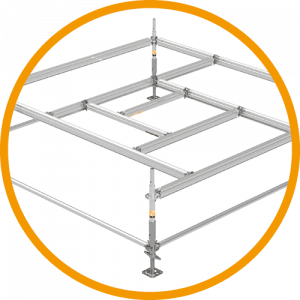

SAFE AND FLEXIBLE

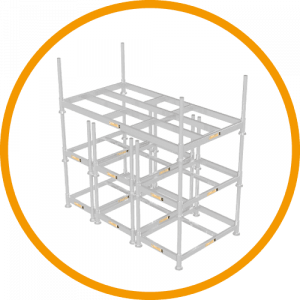

The NO LIMIT™ system uses the metric grid system. The O-Ledgers, PSI-Transoms, PSI-Decks, MonZon Toeboards™ and MonZon Guardrails™ allow you to mount scaffolds from 25-300 cm in 25 cm intervals in any 90° direction. You can also use Variable Corner Decks for erecting round scaffolds with angles from 0-90°.

ONE SYSTEM FOR EVERYTHING

The ambition in the design work has been to meet our users’ needs and wishes about ONE SYSTEM for handling all problems they encounter on a daily basis as scaffolders. Take a deep look at the pictures to make up your own opinion if we have succeeded or not.

The possibility to mount your system with both frames and standards in the same scaffold makes your planning more flexible. Just put in a PSI-Frame if you run out of Standards or vice versa. You can also erect a narrower 75 cm scaffold, continue with a 300 cm wide platform and then go to 150 cm decking using the same components with the same strength. Can you see that NO LIMIT™ is the ONE SYSTEM for everything?

TIME SAVING WITH NO LIMIT™

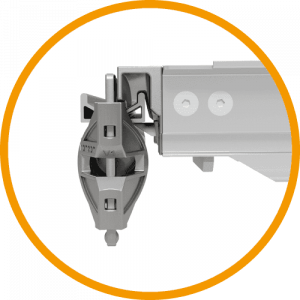

Your timesaving potential with NO LIMIT™ is of course dependent on the complexity of the scaffolds you mount. If you erect straight forward facade scaffolds you will benefit from fewer parts with our developed autolocking system for decking and toeboards.

You will save a lot of time using the MonZon Guardrail™ with its patented flexible wedge heads. You will also save time combining PSI-Frames and Standards because both alternatives use the same components for all types of scaffolds. This means that you can use NO LIMIT™ for any type of scaffolding project.

* The following standards will be available in SCAFFCAD™ during 2019: AS/NZS 1576.3, ANSI SC100-5/05 and CSA S269.2.

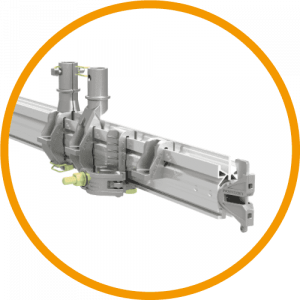

THE PSI-PROFILE IS THE KEY

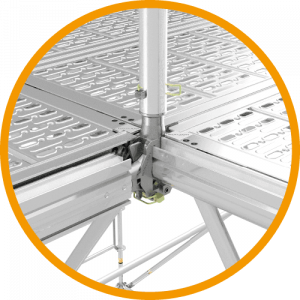

The PSI-Transom in aluminium is very strong and easy to handle. Along with the PSI-Decking and the smart PSI-Couplers they create an autolocking system which gives great flexibility and timesavings.

THE PSI-PROFILE

From the Greek alphabet, the 23rd letter Ψ shares the shape with our ultra strong “PSI” profile. In English this letter is pronounced “sai” or “psai” and will be written “PSI-” for a new range of products in the NO LIMIT™ scaffolding system.

COUPLERS – THE WAY TO CONNECT

PSI-Transoms in combination with the PSI-Couplers make NO LIMIT™ extremely flexible and fast to assemble. You can easily fasten the different PSI-Couplers anywhere on a PSI-Transom or a PSI-Lattice Beam for solving the most difficult scaffolding challenges.

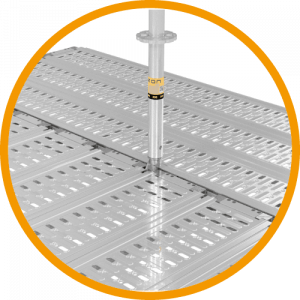

FLEXIBLE LAYOUT - NO LIMIT™ DECKING

PSI-Decks and PSI-Transoms are available in 25 cm increments. This allows for easy mounting around obstacles.

It also saves labor time compared to using timber to cover gaps.

NO LIMIT™ = LIGHTWEIGHT

NO LIMIT™ scaffolding system is made of HIGH QUALITY RECYCLABLE ALUMINIUM. Hydro energy is the main source of the energy used to extrude and produce the components. This makes aluminium the best ENVIRONMENTAL choice and also reduces TRANSPORT COSTS due to its lightweight and innovative design. NO LIMIT™ weighs approximately 50% less than our older MODULAR® scaffolding system in steel!

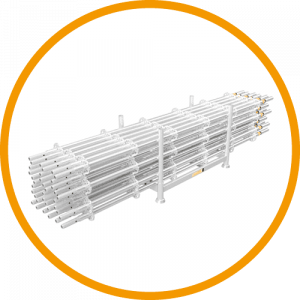

EFFICIENT LOADING - MORE MATERIAL ON YOUR TRUCK

NO LIMIT™ parts such as Standards and O-Ledgers result in fewer transports to and from the construction site. The limitation of a truck usually is the maximum weight and not the volume. In the case of a truck with a maximum load capacity of 23 tonnes, you can normally load scaffolding equipment to mount a scaffold of 6 400 m³.

With NO LIMIT™ components the number goes up to around 8 500 m³. Your advantage is approximately 33% more volume. So, a medium sized scaffolding project saves two-three trips. This means less fuel and working hours which also saves the environment. Your team needs less time to load and unload, reducing the risk of back pain and other restraints.

NO LIMIT™ VS MODULAR®

NO LIMIT™ in comparison with our older multidirectional system MODULAR® which is fully compatible with most of the German-made systems today based on bay lengths of 3.07, 2.57, 2.07 m etc.

This comparison is based on a 24 m long and 1 m wide scaffold, with 4 m to the top deck level and with a 6 m bridge span. The scaffolds had an external ladder bay at one end and stair access at the other. Both scaffolds were assembled by three experienced scaffolders with over 60 years of combined experience with similar scaffolding systems like MODULAR® but only one year of experience with NO LIMIT™.

49% lower weight with NO LIMIT™

26% fewer components with NO LIMIT™

33% faster assembly with NO LIMIT™

50% less labour costs with NO LIMIT™

THE UNIQUE MONZON BACK PAC™ SCAFFOLDING TRAILER

The handling and transport of scaffolding material, during smaller building or renovating projects, is an important issue for handymen and small business owners. With our latest BACK PAC™ Scaffolding Trailer you get a complete package that facilitates your work and helps you turn costs into revenue faster than ever.

- info@monzonscaffold.com

- +46 31 773 04 30

- Monday - Friday: 07:00 - 17:00

- Mon.Zon AB, Box 5238, 402 24 Gothenburg, SWEDEN